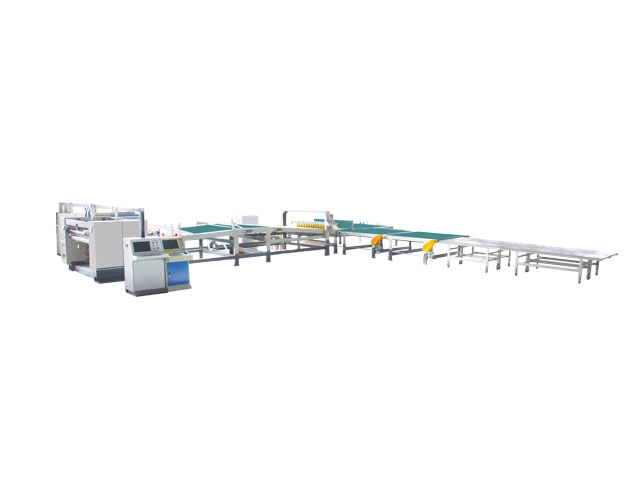

Paper Sheet Delivery & Side Conveyor Machine

- Effective Width: 1400 mm – 2200 mm, Design Speed : 100 m/min – 180 m/min

- Max. Sheet length : 300 mm – 3500 mm

- Automatic Stack and collect cardboard.

- With electromotion transmit horizontally by electric adjustment of backstop position

- Vertical meet cardboard adopts wide conveyor to transmit.

- The sheet or height of cardboard will be moved out by automatic or switch control when reaching request.

Automatic Up Stacking Machine

- Effective width 1400 mm -2500 mm, Design speed: 200 m/min – 250 m/min

- The max, stacking height: 250 mm the max stacking length: 3500 mm

- The automatic change order in 5 second, Automatic counting, and automatic horizontal paperboard delivery.

- Synchronization with production management control system, change order automatically with high speed.

- During working with production manage control system, the waste paperboard less than 700 mm due to change order.

- caterpillar type stacking platform , AC servo control movement, stacking smoothly and tidily.

- Automatic paperboard side delivery when reaching the setting quantity.

- Paperboard dam controlled by AC servo system, Change order automatic and fast, Suitable for small size paperboard stacking.

- Standard electric transport conveyor and double side delivery table

- Individually sealed control cabinet, electrical equipment running in a clean environment

- color touchscreen display for easy field operation

- fully automatic operation control, Improve efficiency, save manpower, reduce labor intensity

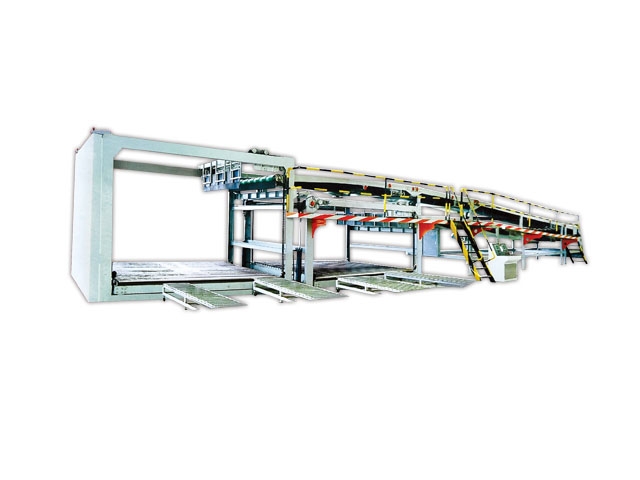

Basket Down Stacker

- Effective working width: 1600 mm- 2500 mm

- Max. working speed: 200 m/min 250 m/min

- Max. Sheet length 3000 mm, min sheet length 500 mm.

- Max Stacking height 1400 mm. ( stacking height not over triplicity of sheet width)

- Automatic sheet stacking and side delivery.

- simplex or duplex down stacker structure.

- Hydraulic Servo valve control of elevator deck, ensure stable and quickly stacking.

- conveyor belt keeping synchronous with production line speed, keep stacking stable.

- PLC Control system to follow production line speed , delivery paper sheet, control elevator deck up and down, control back stop positioning clapboard to achieved automatic order change

- Adopt fiberglass brush press paperboard , and according to paperboard length adjust pressure. Exit of paper sheet delivery with press brush, anti-excursion and guide paper sheet correct delivery.

- Subsection independent driver by AC frequency conversion motor, automatic follow production speed of production line, ensure stable and quickly stacking

- This machine can be connect with production management system to achieved order change and order management.

- Adopt man – machine conversation and touch screen display, easy operation.

- Automatic clapboard setting for sheet and automatic paper sheet side delivery.