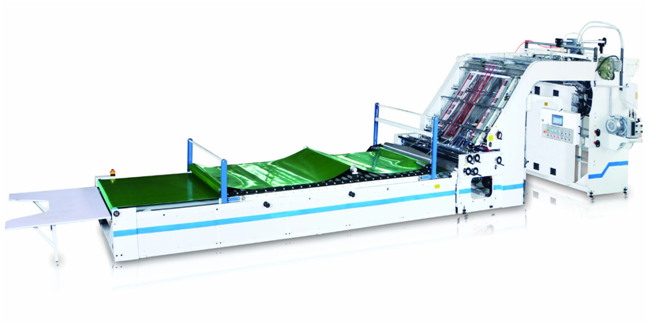

High speed servomotor laminating machine is for the lamination of cardboard to corrugated paper.

Specification

| Model | CY-1450 |

| Max. Sheet Size | 1450x1200mm |

| Min. Sheet Size | 450x450mm |

| Thickness of Surface Paper | 200-800gsm |

| Thickness of Bottom Paper | 0.5-10mm |

| Speed | 150m/min |

| Laminating Precision | ±1mm |

| Dimension | 13500x2450x2400mm |

| Total Power | 25KW |

| Weight | 7.5T |

Features

Computerized operation process, all the operational data is displayed in the computer to improve the work efficiency, lower the working intensity and enhance the quality control.

High speed, can reach 10000 pieces/hour (700mm)

User-friendly, the gluing and distributing glue level are automatically controlled, during high speed running, no splashing, no overflow and backflow.

High precision, sensing adjustment and aligning devices take advantage of several electrical eyes to force the servomotor adjusting separately, the laminating precision can be ±1.0mm.

5.Safe protection is completely, all the electrical parts are in accordance with CE standard.

As the main drive, Siemens motor is adopted with high-end parameters in this industry; the key bearing are with brand NTN covering more than 90%of total bearings

All the electrical parts are controlled by Mitsubishi PLC; speed adjusting by variable frequency, photoelectric sensors are from Omron; the buttons are from Schneider.

Synchronous belt drive is adopted with low noise, the belt are from Gates.

The gluing and distributing system adopt high precision mirror finish roller to control and avoid wasting glue.

Surface paper transferring unit adopt PU round belt combined bottom fans to ensure stable running, the servomotor in both side can adjust paper position.

The feeder of the high speed laminating machine is a key part, as our supplier Fanyu Ruida is very professional and famous in this industry.

The steel wall of the main body are machined by CNC to avoid the misfit of the two side walls.The covers are manufactured by CNC to make the appearance better, structure more reasonable. The surface of cover are electrostatic sprayed.