Features

- Touch screen controls in each movable unit with PLC. And be able to interconnect with integrated computer. All function operation and order setting are available with digital display.

- Integrated drive and safety protection device is used for pneumatic interlocking over each unit.

- All transmission gears are carburized and quenched with precisely ground. When the machine running, every corner of gears is lubricated by the recycle sprayer.

- All core components are from the international top brand.

- In-line control of flexo printer combined with folder gluer. Integral order management and quick shift function are available. It made the significant revolution for the completely automatic production line in the packaging field.

Main Technical Parameter

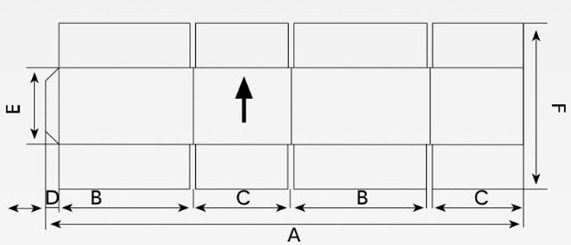

| Technical date (MM) | |||

| Max.size | 2800 | ||

| Max. sheet length (A) | Min.size | 720 | |

| Continuous feed | 1200 | ||

| (F) Max. sheet width (F) | Skip feed | 1400 | |

| Min. sheet width | 350 | ||

| Max.Printing area (FxA) | 1160×2750 | ||

| Reverse knife | Max.size(B) | 1100 | |

| Min.size(B) | 270 | ||

| Slotting space | Max.size(C) | 940 | |

| Min.size(C) | 100 | ||

| Normal knife | 1040 | ||

| 160 | |||

| Slot depth | Max.size | 320 | |

| Box height(E) | Min.size | 110 | |

| Max.die-cutting size | 1150×2750 | ||

| Working Speed | Top speed( pcs/min.) | 200 | |

| Economic speed | 100-180 | ||

| Sheet thickness | 1.5-11 | ||

| The thickness of the printing plate | 7.2 |

Feeding Unit

- Mechanical Lead edge feeder

- Skip feeding is available

- Sheet cleaning system includes upper suction motor and brusher.

- Motorized control of the movement of Unit On-Off. For safety, an audible alarm sounds while the units moving.

- Frequency control of the main motor and there is a protective device for main motor running. (the machine can’t run when the units are not locked).

- The pneumatic brake device is attached to the driving shafts to avoid machine damage while there is a faulty operation.

- PLC control, touch screen operation, and pneumatic self-locking system.

- It could reduce the feeding error and increase the printing accuracy, slotting, and die-cutting

- Little vibration and speed-up.

- Frequency converter controls the air volume of suction. And correctly adjusted by a sectional knob.

- The volume and pressure are manually controlled to match different sizes of paperboard.

- The side guides (right-left movement) are motorized,Back stop (descending & ascending) is manual, Backstop (front/back) is motorized. The front guide is manual

- Side squarer set along with the side guide.

- After all, units close, the machine returns to zero position automatically. To reduce the time of proof printing.

- The Upper feeding roller is made of quality steel and covered with wear-resisting rubber, surface grooved; the hardness of rubber is 38 degrees; Also cylinder buffer device is adapted to avoid paperboard breakage.

- The lower feeding roller is engraved and hard chrome plated, increasing friction to ensure feeding accuracy.

- The second upper feeding roller with 4pcs creasing rings, which is covered with wear-resisting rubber. The rubber surface grooved to avoid the damage of paperboard strength

- The Second lower robber made of seamless steel pipe, which balance corrected and precisely ground and surface chromed.

- The pressure of lower roller is manually adjusted, dial indicator, the adjustment range is 0-11mm.

Printing Unit

Printing cylinder

- It is made of seamless steel pipe, which balances corrected and chrome plated and surface ground. The shaft core treated with thermal refining, which makes becoming wear-resistance.

- Printing cylinder diameter:

Model

CLC-Q2-1228

Outer diameter

Ф394mm

Including printing plate

Ф408mm

- The entire printing plate slot is fit for 3x10mm printing plate hang-up bar.

- Loading and unloading the printing plate could be controlled electronically by the pedal switch.

- Safety control button set along with the pedal switch ensure the operator’s security when loading &cleaning the printing plate.

- Equipped with a safety button for loading and unloading the printing plate

Roll to Roll Transfer

- The lower pressure roller is made of seamless steel pipe, precision ground, chrome plated and balance corrected, and the thermal refining of shaft core to make it become more anti-fatigue and toughness.

- The pressure of lower roller is manually adjusted, dial indicator, the adjustment range is 0-11mm.

- The upper guiding roller is made of solid steel pipe, precision ground, chrome plated and balance corrected, with 2pcs grooved guiding rings, can be quickly adjusted by hand.

- The lower guiding roller is made of seamless steel pipe, precision ground, chrome plated and balance corrected, with 2pcs grooved guiding rings, can be quickly adjusted by hand.

- The pressure of guiding roller is manually adjusted, dial indicator, the adjustment range is 0-11mm.

Rubber roller (inking roller)

- Rubber roller is made of seamless steel pipe, precision ground, chrome plated and balance corrected.

- The surface of the steel pipe is covered with wear-resisting rubber, which is ground precisely to achieve a better inking

- The rubber roller will keep running when the machine is stopped, it is driven by a reducer motor

- The pressure between rubber roller and anilox roller is manually adjusted, dial indicator, the adjustment range: 0-6mm.

Steel anilox Roller

- Anilox roller is made of high-quality seamless steel pipe, and the shaft head adopts shrink fitting technologies, precision ground, chrome plated and balance corrected.

- The delay function is adapted for feeding system automatically lifting.

- The pressure between anilox roller and printing cylinder is manually adjusted, dial indicator, the adjustment range: 6-9mm.

Phase Register

- Planetary gear structure with 360º precisely adjustable for printing register.

- Printing register adjust is motorized, which can be automatically reset. The printing cylinder lateral adjustment ± 7 mm

- Fix register is pneumatically controlled by brake structure. When the units are opening or registering, Brake structure stops the machine running to keep the print plate position.

Ink Supply system

- Pneumatic diaphragm ink pump, inking evenly, operate and maintain easily.

- Ink barrel cover is made from stainless steel, long service time. Being Sprayed Teflon inside the wall, the cover would be easily cleaned.

Pre-creaser at last printing unit

- The pre-creaser device is added with the last printing unit, which is able to move quickly by hand, the gap is manually adjusted, dial indicator, the adjustment range: 0-11mm.

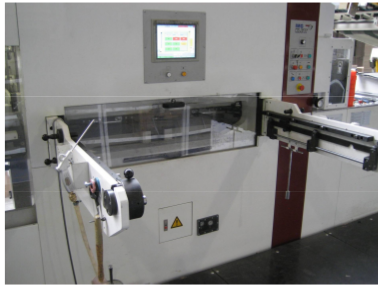

Chambered Doctor Blade(optional)

- Chambered Dual-doctor blade system is adopted, ensure inking well-distributed and eliminate color tolerance. While rubber inking roller can bring the color tolerance caused by high-speed centrifugation.

- Airbag doctor blade system used for making more excellent inking distribution and avoid color tolerance.

- Nylon doctor blade used for reducing friction. Chambered doctor blade with double side ink pump to save ink and time of cleaning

- Quick replacement of doctor chamber

- Position set of doctor blade holder can be quickly controlled by hand.

Ceramic anilox roller (Optional)

- Ceramic anilox roller is made of high-quality seamless steel pipe, and the shaft head adopts shrink fitting technologies (not welding) and tempering treatment. The surface sprayed with ceramic, precision ground. The using life is three times longer than normal anilox roller.

- Precision laser engraving mesh, the number of lines and the amount of ink containing uniform, 250-800 lpi available.

- Balance corrected and stable running

- The delay function is adapted for feeding system automatically lifting

- The pressure between the anilox roller and printing cylinder is manually adjusted with dial display, the adjustment range: 6-9mm.

Slotting Unit

Pre-Creaser

- Creasing Upper/Lower shaft: It is made of quality steel pipe, surface chrome plated, and ground precisely and stable running. And it was equipped with four groups creasing rings.

- Pre-creasing shaft diameter

Model

CLC-Q2-1228

Outer diameter

Ф135mm

- Upper creasing ring is covered by rubber, and the rubber on the creasing ring is dismountable. Quick change.

- The gap of the pre-creasing roller is manually adjusted with the self-locking system, dial indicator, the adjustment range: 0-11mm.

Creasing Roller

- Creasing Upper/Lower rollers: It was made from solid steel pipe, surface chrome plated and ground precisely stable running, and it was equipped with four groups creasing rings

- Creasing roller diameter

Model

CLC-Q2-1228

Outer diameter

Ф135mm

- Upper creasing ring is covered by rubber, and the rubber on the creasing ring is dismountable. Quick change.

- The gap of creasing roller is manually adjusted with the self-locking system, dial indicator, the adjustment range: 0-11mm

Slotting knife shaft

- It was made from solid steel pipe, precisely ground and surface chrome plated, sunning stably

- Slotting knife diameter

Model

CLC-Q2-1228

Outer diameter

Ф170mm

- Slotting Upper knife is made of alloy steel, with the width of the knife is 7mm, heat treatment and precisely ground. The hardness is HRC60-63

- Slotting lower knife & Trimming knife are made of alloy steel with heat treatment and precisely ground. The hardness reaches to international standard HRC60-63, and shape blade for precisely trimming.

- Lighting lamp is attached at the top of the pull arm above the slotting knife in case of the night working.

- Single shaft double slotting knife.

- Installed with a dial indicator, the slotting boss moves precisely along linear guides and driven by motorized with lead screws. Computerized with Order management is available.

- Synchronized four group of slotting knife to adjust the Box height, which connected with PLC. Both Order Managing System and Motorized setting are available

- The gap of pull roller is adjusted manually, dial indicator, and the adjustment range: 0-11mm.

- Central-knife is moveable

Slotting register adjustment

- Planetary gear structure is adopted for slotting register, 360ºprecisely adjusted.

- Slotting register digitally controlled by touch screen and PLC. It could be controlled by a motor with the display as well.

- Fix register is pneumatically controlled by brake structure. When the units are opening or registering, Brake structure stops the machine running. So that keeps the slotting roller position

- The main control panel is set in this unit. The transversal, box height, and slotting register can be adjusted with the order management system or can be motorized adjusted also.

Die-cutting Unit

- Made from seamless steel pipe, using shaft-lock structure and shaft core treated with thermal refining, chrome plate, and surface ground.

- Roller diameter

Model

CLC-Q2-1228

Outer diameter

Ф389m

Including die

Ф405mm

- Hardened steel cover with pneumatic-lock cylinder set at upper roller can hence durability of using.

- Die-cutting anvil is covered by rubber(Made from Italy). Ring mounting structure is adopted.

- Mechanical differential structure is applied for the adjustment of transverse register. The adjustment range is ±30mm. Its movement keeps the surface of rubber flat and smooth. Taiwan anvil rubber is used

- The gap of die-cutting anvil is manually adjusted; with dial indicator, and the adjustment range: 0-15mm.

- With automatic anvil grinding knife, The Anvil rubber can be used circularly and prolong its lifetime.

- Die-cutting anvil is designed with One-way clutch Mechanical linear speed compensation. As customers request, Frequency control of the independent motor for line speed compensation is optional.

Die-cutting cylinder

- Made from seamless steel pipe, using shaft-lock structure and shaft core treated with thermal refining, chrome plate, and surface ground.

- Outer diameter

Model

CLC-Q2-1228

Outer diameter

Ф360 mm

Including die

Ф408 mm

- Crossline engraved on the surface of the die-cutting cylinder. M10 screw holes are attached on the surface of the cylinder. And holes distance is the international standard.

- Wooden die height is H25.4mm for installation

- Lighting lamp is installed on the pull arm above the cylinder, for night work.

Guiding Upper/Lower roller

- Upper roller is made from solid steel pipe, equipped with two sets of creasing rings, which are able to quickly move along with rack and control manually.

- Lower roller is surface ground and chrome plated, balance corrected and stable running.

- The gap of lower roller is manually adjusted with the self-locking system, dial indicator, the adjustment range: 0-11mm.

Die-cutting register adjustment

- Planetary gear structure, 360ºprecisely adjusted.

- Die-cutting register is digitally motorized, auto zero and auto reset.

- Die-cutting cylinder transverse moving is digitally motorized, and the adjustment range: ±5mm.

- Fix register is pneumatically controlled by brake structure. When the units are opening or registering, Brake structure stop the machine running. So that keeps the die-cutting cylinder position.

Folder Gluer & Counter Ejector

Folder Gluer Device

- In-line control of printing unit, touch screen panel.

- This machine adopts bottom folding system in-line with top printer to prevent adhesion rebound.

- Servo control of roller gluing system, electrical spraying system is optional.

- Air suction control of upper folding belts, right/left belts can be adjusted freely.

- The position setting digitally control, and can be operated in each printing unit.

Counter Ejector Device

- There is a space for temporary storage and flap after folding and gluing to ensure cartons well-glued and fixed.

- Vacuum adsorption for paper-out, quick set, precise counting.

- Stacking unit designed with elevation structure to protect carton damage, quantity pre-set, neat stacking, auto ejecting, bundling unit is optional.

- The position setting digitally controlsAccurate counting/auto stacking/auto ejecting and can be the easy match with bundling unit (Bundling unit – Optional).