Technical Data

|

1 |

Number of Operator |

9 persons |

|

Mill Roll stand & Single Facer: 1 Double Facer: 1 Slitter Scorer & Cut-off: 1 Stacker: 2 Boiler: 1 Glue system: 1 Chief:1 |

||

|

2 |

Running Width |

1800mm |

|

950mm |

||

|

3 |

Max Speed |

100 m/min |

|

4 |

Working Speed |

80m/min |

|

5 |

Monthly Output |

500~800tons (1 shift with12 hours /day, 24 working days/ month) |

|

6 |

Maximum sheet size |

1800mmX 3000 mm |

|

7 |

Minimum sheet size |

125mmX500mm |

|

8 |

Paper Grades |

90 g/csm – 180 g/csm (Medium) |

|

110 g/csm – 400 g/csm (Liner) |

||

|

9 |

Adhesives Required |

starch |

|

10 |

Starch consumption |

3 ply: 10-15g/㎡ 5 ply: 20-30g/㎡ |

|

11 |

Steam Pressure |

1.2 MPa |

|

12 |

Steam Consumption |

Approx. 2800~3000kg/h |

|

13 |

Occupied Space |

Approx. 10 m X 48m (Incl. operation space) Highest point is 4.25m |

|

14 |

Power Capacity |

Approx : 181Kw |

|

15 |

Power Required |

380V, 50HZ, 3 PHASE |

|

16 |

Paper going |

Drive side (left hand or right hand) |

|

17 |

Flute |

A, B, C or E (UV flute) |

|

18 |

Delivery |

120 days after the receipt of down payment |

|

19 |

Quality Guarantee |

1 year after installation |

Commodity Name, Quantity

| No. | Name | Qty |

| 1 | 800A Rails & Trolleys+ZP350Turnplates | 3 |

| 2 | WZJ-A1800 Mill Roll Stand (Motorized lifting and clamping, pneumatic brake, expansion chuck) | 3 |

| 3 | DMWL-A1800 Single Facer (steam heating, fingerless, Tungsten corrugating roll A/B/C Flute) Flute type is to be confirmed) | 2 |

| 4 | XYR420-1800 Pre-heater | 4 |

| 6 | YRA600-1800 Triple Pre-heater | 1 |

| 7 | GQ1800-II Conveyor Bridge | 1 |

| 8 | RMJ-1800-II Gluer | 1 |

| 9 | ZH-A1800 Double Facer (425mm*13 pieces hotplates, pressure rolls, upper belt cleaning device, temperature digital readout) | 1 |

| Drive Roll Stand (variable frequency control) | 1 | |

| 10 | SBFY-A1800 Slitter Scorer (4outs, Variable frequency control) | 1 |

| Trim shredder system | 1 | |

| 11 | DHQ1800 NC Cut Off (simplex) | 1 |

| 12 | DS Stacker(simplex) | 1 |

| 13 | ZJD Glue preparing and Supplying system | 1 |

| 14 | Compressed Air system | 1 |

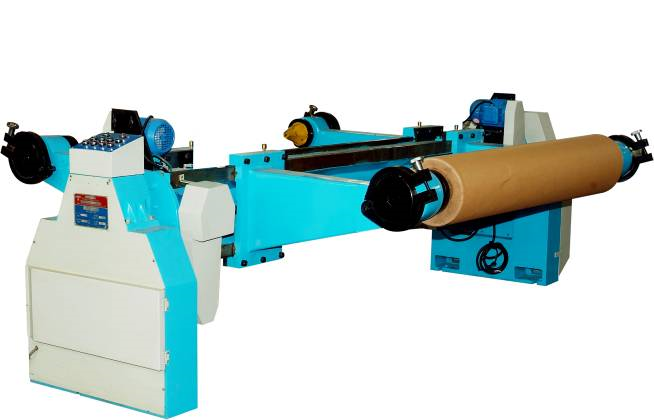

Mill Roll Stand (Mechanically)

Main Structure and Features

- Motorized lifting and lowering with overload protection device

- Motorized clamping/unclamping and centering with overload protection device

- HT200 Iron cast clamping arms

- Solid operation cabinet

- Pneumatic web tension adjustment

- Expansion chuck

Main Structure and Features

- Motorized lifting and lowering with overload protection device

- Motorized clamping/unclamping and centering with overload protection device

- HT200 Iron cast clamping arms

- Solid operation cabinet

- Pneumatic web tension adjustment

- Expansion chuck

Single Facer (Fingerless)

Main Structure and Features

- Excellent appearance and compact structure

- Vacuum suction Fingerless design provides perfect flute formation and is free of high-low flutes

- Corrugating roll (with diameters of Φ263/Φ266), 48CrMo alloy steel, and induction hardened with hardness up to HRC55~60, which provides remarkable wear resistance and long life

- Main bearings, lubricated with high-temperature grease, selected to provide outstanding sealing performance and reliable lubricating.

- Applicator roll loading and unloading are pneumatically controlled with quick response and excellent impact absorption

- Gap adjustment between applicator roll and doctor roll is accomplished by worm and worm wheel mechanism

- Self-circulating glue system, applicator roll is immersed within glue pan

- Pressure roll (Φ262.5), applicator roll(Φ210) as well as doctor roll(Φ118), top quality forged steel, also hard chrome-plated and ground.

Main Technical Data

- Designed speed:100m/min (steam heating)

- Available width: 1800mm

- Available paper width : 850~1800mm

- Total power: 33Kw

Overhead Bridge Mounted Pre-heater

Main Structure and Features

- Preheating Roll:There is steam in the roll to heat the web or single-faced web.

- Tensioning Roll: Guide the moving of the web.

- Wallboard: To support and locate the machine.

Main Technical Data

- Available width: 1800mm

- Pre-heating roll diameter: Φ420

Pre-heater

Main Structure and Features

- Rotary preheating roll driven by paper with manual brake enhances heat conduction.

- Motorized wrap angle adjustment, meeting different paper and working speed.

- Spraying device for pre-conditioner to adjust moisture content of the fluting paper

Main Technical Data

- Available width: 1800mm

- Pre-heater roll diameter: Φ600mm

- Wrap angle adjusting range: 600~2200

- Power: 0.55kW (for wrap roll adjustment)

Overhead Bridge Conveyor

Main structure and Features

- Frame made of channel iron, angle iron and iron plate, the main frame made of І-shaped steel.

- Handrail and full covered reinforced footplates for safety protection.

- Inclined belt conveyor with cotton belt for single-faced web lifting.

- For DMWL-A single facer, synchronization is realized with chain by single face.

- Motorized web running controller

Suction tension control device

- Vacuum suction to tension the web. Vacuum blower force is adjustable.

- Vacuum suction box with width-related suction range.

- Motorized web edge alignment.

- Two sets of operator control panels with one at bridge and the other at glue machine.

Glue Machine

Main Structure and Features

- Pneumatic pressing with quick acting and non-waste

- Self-circulating glue supplying system with adjustable glue quantity

- Preheating device quickens glue gelling

- Synchronization with line is kept with external drive source

- High precision engraved and hard-chrome plated applicator roll (30LPI)

- Hard chrome-plated pressure roll, doctor roll, preheating roll as well as guide roll

Main Technical Data

- Available width: 1800mm

- working speed: 100m/min

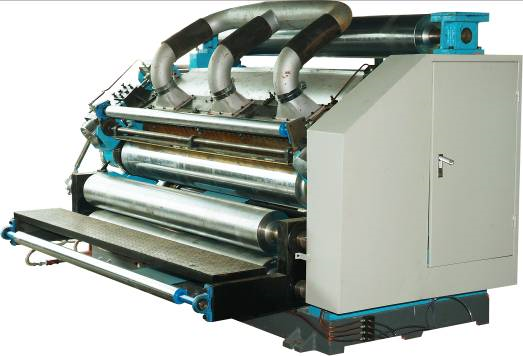

Double Facer

Main Structure and Features

- Surface ground steel hot plates, 490mm wide, are of inner whirlpool structure, favorable for steam distribution

- Dense weight rolls of heating unit are lifted and lowered as a whole with motorized height adjustment.

- Dense weight rolls of cooling unit ensure perfect forming quality.

- If configured with mechanical cut-off, the drive unit must be driven with external power source, while with computerized cut-off, the drive unit is driven with self-power.

- Pneumatic tension for upper belt

- Large engraved drive roll stand (Φ625mm), covered with herringbone wearable rubber

- Hard chrome-plated weight rolls as well as guide rolls

- Hot plates: 13

Slitter Scorer

Main Structure and Features

- Precision ball lead screws for tools setup

- Manual tool setup

- Adjustable slitting depth and easy blade disengagement.

- Scoring head introduces whole mechanism design with little radial and end face run-out

- Self drive source, synchronizing with the line automatically.

- Motorized adjustment for scoring depth to meet different caliper needs

- Motorized lateral adjustment for the whole machine to meet web deviation.

- New thin blade enables clean cutting edge at high speed.

- Automatic blade-regrinding and blade-lubricating devices keep tool-edge sharp during operation and saves maintenance time.

- Pneumatic lifting and lowering of working station for quick order changeover.

- Male-to-female scoring profile

- 4 outs

Main Technical Data

- Available width: 1800mm

- Designed speed: 150m/min

- slit-to-slit distance: 125mm

- score-to-score distance: 80mm

- Tool set up precision: +1

- Total power: 8.3kw (without blower) 3kw (with blower)

Trim Shredder

- Shred the waste side trim and scrap out from the slitter scorer, then convey to the waste-collecting site through high-pressure suction tube.

- Mass flow, high pressure, strong shredding force, and long conveying distance.

- Especially suitable for medium or advanced level production line

- Working pressure: 4000Pa

- Air flow: 4200m3/h

- Shredding capacity: 1.5t/h

Cut-off

Main Structure and Features

- It is the upgraded version of DHQ

- Two knife rolls rotate to cut the board with shearing difference, featuring lower cutting force and lower noise

- Precision adjustable anti-backlash gears ensure accurate mesh between knives

- Computerized order management system

- The drive unit is driven with self-power.

- Knife bars: Φ245, fine-machined & treated with dynamic equilibrium

- Cut knives: Quenched steel, T8A

Main Technical Data

- Designed speed: 100m/min

- Available width: 1800mm

- Cutting length: 500~3000mm

- Cutting precision: ± 1mm

- Total power: 39 kW

Compressed Air System

- Supply compressed air to the complete line, keeping stable working pressure.

- Centralized air supplying with air compressing station.

- Compressed air filtered at the inlet is clean and stable.

- Individual control of each unit independently of each other.

- Adjustable pressure with pressure meter for each unit.

- Accessorial copper pipes and PU pipes are wearable.

- Re-filtered and lubricated with oil mist prior to entering each machine.

- Integrated pneumatic and electric control system with one operation panel, featuring easy and convenient remote operation.

- Two 0.6m3/min air compressors (power: 3.7kW/set) for lower speed single wall production line.

- Two 0.9m3/min air compressors (power: 5.5kW/set), and 1.5m3 air storage tank for double wall production line and singe wall line with width more than 2200mm.

- Three 0.9m3/min air compressors (power: 5.5kW), and 2.5m3 air storage tank for triple wall production line.

Glue System

- Supply starch adhesive for single facer(s) and glue machine.

- Horizontal mixer confects the main glue and carrier glue and then mixes them enough with large volume. The storage capacity of main glue is 1.42m3, Mixer motor power is 5.5kW; the storage capacity of carrier glue tank is 0.57 m3, mixer motor power is 2.2kW.

- Storage tank and supply tank is equipped with mixing device, preventing glue from depositing. Storage capacity of storage tank is 1000L. Mixer motor power is 1.5 kW.

- Self-circulating glue supplying system with 280L glue return tank on the ground. Automatic glue level control. The returned glue is pumped to the storage tank with self-priming pump (power: 1.5 kW) and then flows to relevant equipment, avoiding glue gelling and solidifying in the glue pan.

- Individual glue preparing system is flexible for glue room layout.